Food grade plastics, i.e. plastics intended for contact with food and beverages, are a special form of certified plastics for food applications. Modern production processes in critical industrial areas (e.g. pharmaceutical or food) require special materials that will guarantee purity and stability. Without these materials, the risks of production processes in the above industries would be too great. The topic of risks is increasingly relevant even for production capacities in modern production facilities, where a sudden change or contamination that can occur within the processing processes will cause not only immediate damage on an industrial scale, but also secondary consequences of the same magnitude. As a result of the emphasis on safety, there is a need to invest in research into innovative materials that will allow control or completely prevent a critical factor in the food industry, namely the possibility of contamination.

Food grade plastics, i.e. plastics intended for contact with food and beverages, are a special form of certified plastics for food applications. Modern production processes in critical industrial areas (e.g. pharmaceutical or food) require special materials that will guarantee purity and stability. Without these materials, the risks of production processes in the above industries would be too great. The topic of risks is increasingly relevant even for production capacities in modern production facilities, where a sudden change or contamination that can occur within the processing processes will cause not only immediate damage on an industrial scale, but also secondary consequences of the same magnitude. As a result of the emphasis on safety, there is a need to invest in research into innovative materials that will allow control or completely prevent a critical factor in the food industry, namely the possibility of contamination.

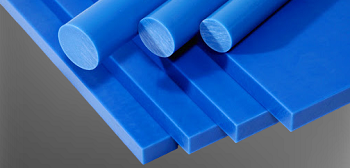

Food grade plastic supply:

|

SPECIFIC GRAVITY | MODULUS ELASTICITY | TENSILE STRENGHT | IMPACT STRENGHT | WATER ABSORPTION | SERVICE TEMPERATURE |

SEMI-PRO ▉ plates ● rods ◎ tubes |

TECH SHEET |

|||

| gm / cm3 | MPa | MPa | ShD | % | °C |

||||||

| DIN ISO 1183 | DIN ISO 527 | DIN ISO 527 | DIN ISO 868 | DIN ISO 62 | krátk. | dlouhodobě | |||||

| PTFE | 0.96 | 1200 | 27 | 65 | 0.01 | 100 | -100…80 | 🟥 🔴 ⭕ | |||

| DTEKBLUE | 0.91 | 23 | 55 | 260 | -200..260 | 🟥 🔴 ⭕ | |||||

| UHMW-PE | 0.93 | 680 | 20 | 63 | <0.01 | 130 | -250…80 | 🟥 🔴 ⭕ | |||

Plastic resistance:

| ABRASION RESISTANCE | UV RESISTANCE | FLAME RESISTANCE | ACID RESISTANCE | ALCALI RESISTANCE | SOLVENT RESISTANCE | ||

| PTFE | ✖ |  |

|

|

|

|

|

| DTEKBLUE | ✖ |                  |

|

|

|

|

|

| UHMW-PE |                  |

|

|

|

|

|

|